Quartz Grits/Granules

Delivering Precision and Reliability with Quartz Grits/Granules

Introducing Our Associate Company in Quartz Grits/ Granules.

Dadi Minerals, our esteemed associate or in simple words partner company is our trusted supplier, renowned for delivering high-quality Quartz Grits/Granules. Our expertise in this company is manufacturing top-notch quartz grits/granules and our commitment to excellence ensures that our clients receive a premium quality of Quartz Grits/Granules. With state-of-the-art facilities and a skilled team, we at Dadi Minerals consistently meet our client’s requirements and exceed their expectations with us. Our reliable and consistent supply of top-notch quartz grits/granules has cemented this company’s position as our valued partner in providing exceptional Quartz Grits/Granules. We take pride in our partner company “Dadi Minerals” in serving the pledged commitment to providing the highest quality Quartz Grit/Granules.

Product Description

We specialize in manufacturing high-quality quartz grits/granules. Our manufacturing process involves crushing and grinding carefully selected quartz rocks to obtain the desired particle sizes. We ensure that our quartz grits/granules are free from impurities and have a consistent and uniform texture. Our grits/granules are known for their exceptional hardness, durability, and abrasive properties, making them ideal for a wide range of industrial applications.

Whether it's for grinding, polishing, sandblasting, or surface preparation, our quartz grits/granules deliver excellent performance and precision. We strive to meet the specific requirements and demands of our customers by offering a reliable and superior product for various industrial processes.

Features Of Quartz Grits Granules

- Scratch resistance

- Accurate cutting

- Excellent durability

- High chemical and physical properties

- Accurate composition

- Cost effective

- Highly effective

Properties Of Quartz Grits Granules

- Port of Dispatch: PIPAVAV / MUDRA PORT

- Production Capacity: 1000 mtons/month

- Delivery Time: 2 weeks

- Packaging Details: 50 kg Jumbo bags

- Quartz is consisting of high-purity silica in amorphous (non-crystalline) form.

- Quartz is a very common mineral in the Earth crust. It has been proved that quartz is the second most widely available mineral on the continental crust of the Earth, covering almost of it, beaten only by feldspar.

- Chemically, quartz is silica, or silicon dioxide, SiO2.

- It is found in most types of rocks: Igneous, metamorphic and sedimentary.

Product Details:

| Product Type | Minerals |

| Types of Refractories | Neutral Refractory |

| Color | White |

| Supply Ability | 100 Ton Per Day |

Product Specifications

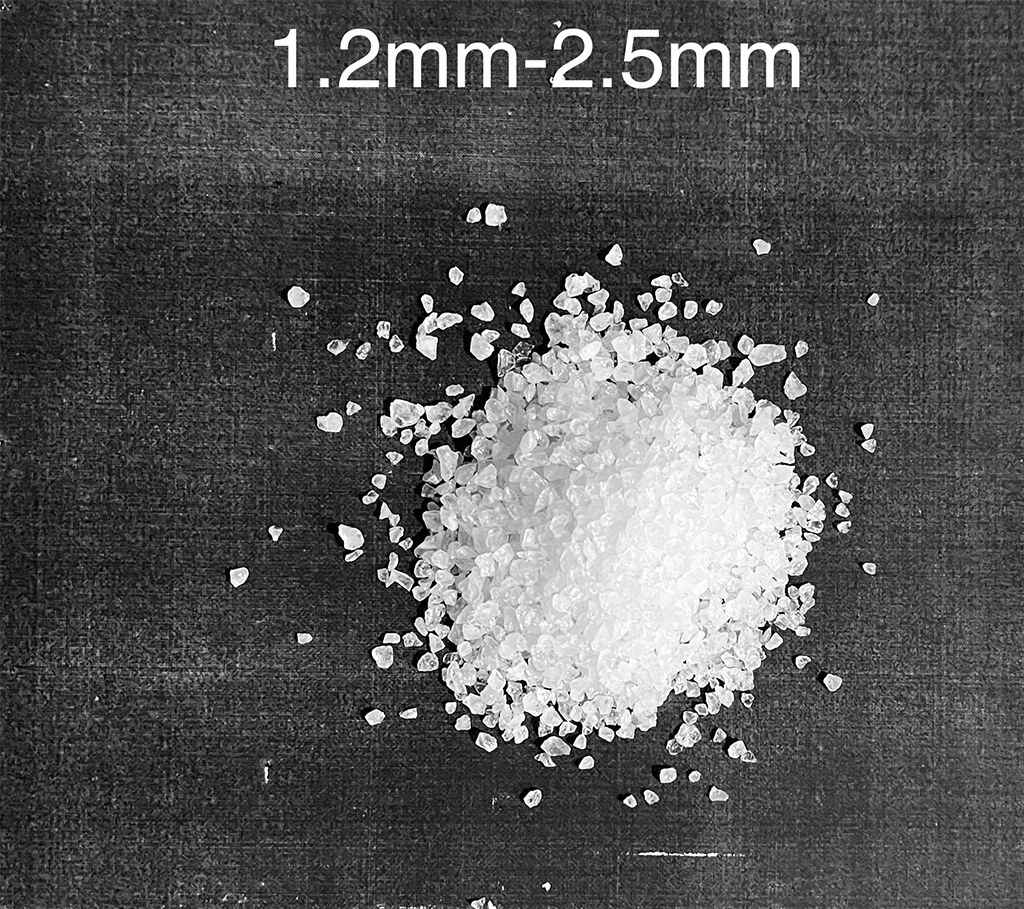

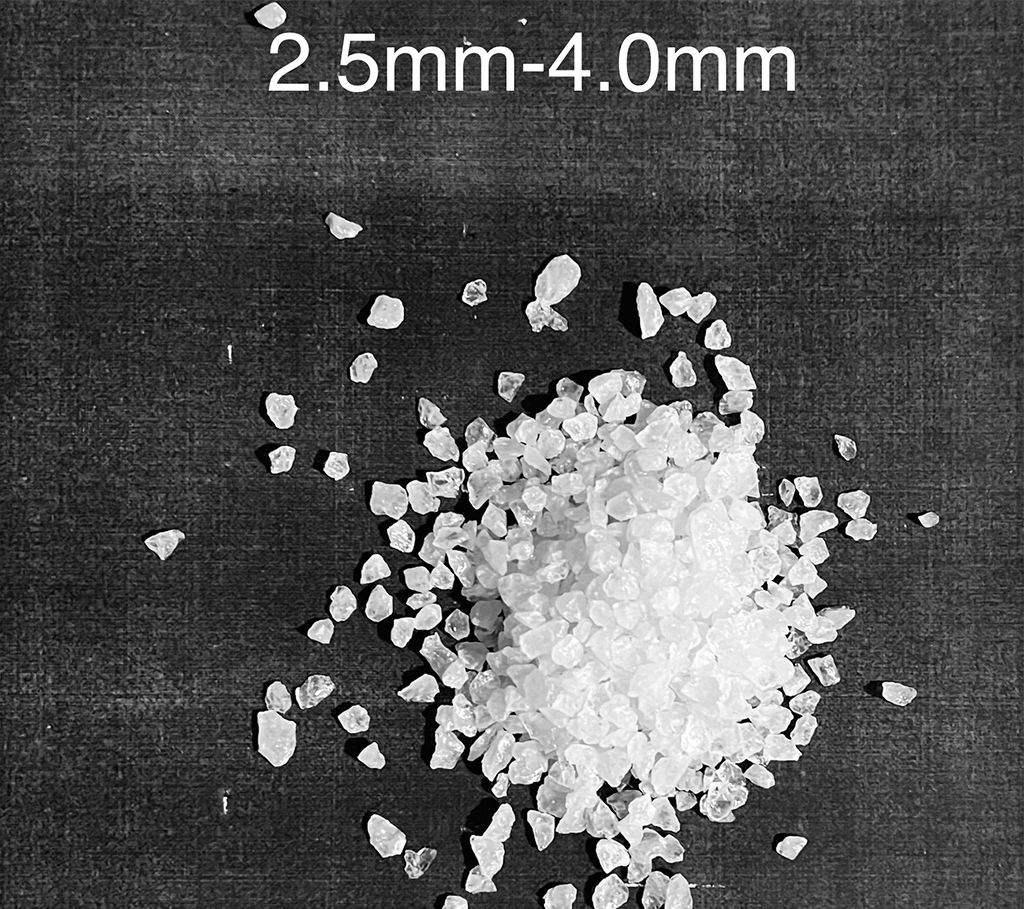

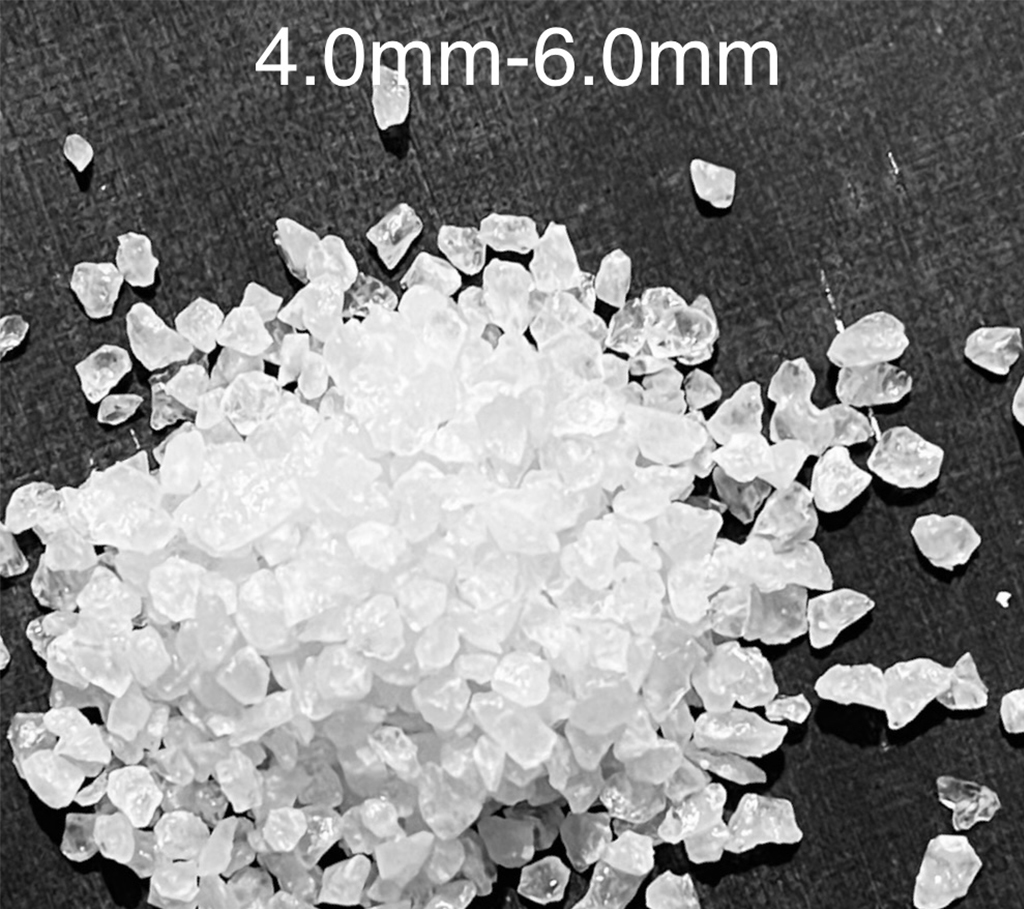

We offer a diverse range of Snow White Quartz Grains in various sizes, ensuring we meet the specific needs of our customers.

These sizes include

0.1mm-0.4mm,

0.3mm-0.7mm,

0.6mm-1.2mm,

1.2mm-2.5mm, and

2.5mm-4.0mm.

Each size maintains a mesh variation of (+, -)5%. Our quartz grains boast a minimum purity of 99.5% SiO2 (Silicon Dioxide) and a maximum iron content (Fe2O2) of 0.01%. Their transparent color adds to their aesthetic appeal. With our commitment to delivering consistent quality, customers can rely on our Snow White Quartz Grains to meet their specific industrial requirements, ensuring optimal performance and reliability in various applications.

Trade Information

| Supply Ability | 100 Ton Per Day | Delivery Time | 10 Days |

| Sample Available | Yes | Sample Policy | Free samples are available |

| Packaging Details | As per customer requirement | Main Domestic Market | All India |

| Certifications | yes |

Uses Of Quartz Grits Granules

Engineered Quartz

Quartz grit is a crucial component in the production of engineered quartz. It provides the necessary hardness, consistency, and abrasive properties required to create durable and aesthetically appealing engineered quartz surfaces for countertops, flooring, and other applications

Glass Making

Quartz grits/granules play a crucial role in the production of glass. They are used as a key ingredient in glass formulations, contributing to its transparency, hardness, and thermal resistance. Additionally, they facilitate the melting process and help to control the viscosity of the molten glass.

Solar Industry

Quartz grits/granules are used in the solar industry as a key component in the manufacturing of solar cells. The high purity and thermal stability of quartz make it an ideal material for creating the silicon wafers used in solar panels, enhancing their efficiency and durability.

![]()

Silicon Metal Wafers Industry

Quartz grit is utilized in the silicon metal wafers industry for its crucial role in the production of semiconductor wafers. It provides a high-purity and stable substrate, contributing to the manufacturing of high-quality silicon wafers used in electronic devices and integrated circuits.

Cosmetic Industry

Quartz grits/granules are utilized in the cosmetic industry as exfoliating agents in various skincare and beauty products. Their gentle yet effective abrasiveness helps remove dead skin cells, unclog pores, and improve the overall texture and appearance of the skin.